1. Reasons for delays: chain, materials, prices

There is a shortage of key materials in the UAE construction market due to inflation and instability of global supplies. The demand for steel, cement and other goods exceeds the supply, which leads to higher prices and delays.

In response, Dubai developers are shifting to local supply chains to reduce the impact of tariffs and ensure the sustainability of the project.

2. Strategies of cable tray manufacturers

Supply diversification

Cable tray suppliers are actively looking for alternative steel suppliers in the region and neighbouring countries to reduce dependence on import routes.

Local warehouse and buffer logistics

The presence of warehouses in the ports of Jebel Ali and Abu Dhabi allows cable tray suppliers in Dubai to promptly deliver ready‑made trays, even with delays in the import of components.

Planning with a margin

A methodology for long-term ordering and early redundancy of materials used to reduce the impact of delays, as is done on infrastructure projects.

3. Engineering approach to production for mega‑scale projects

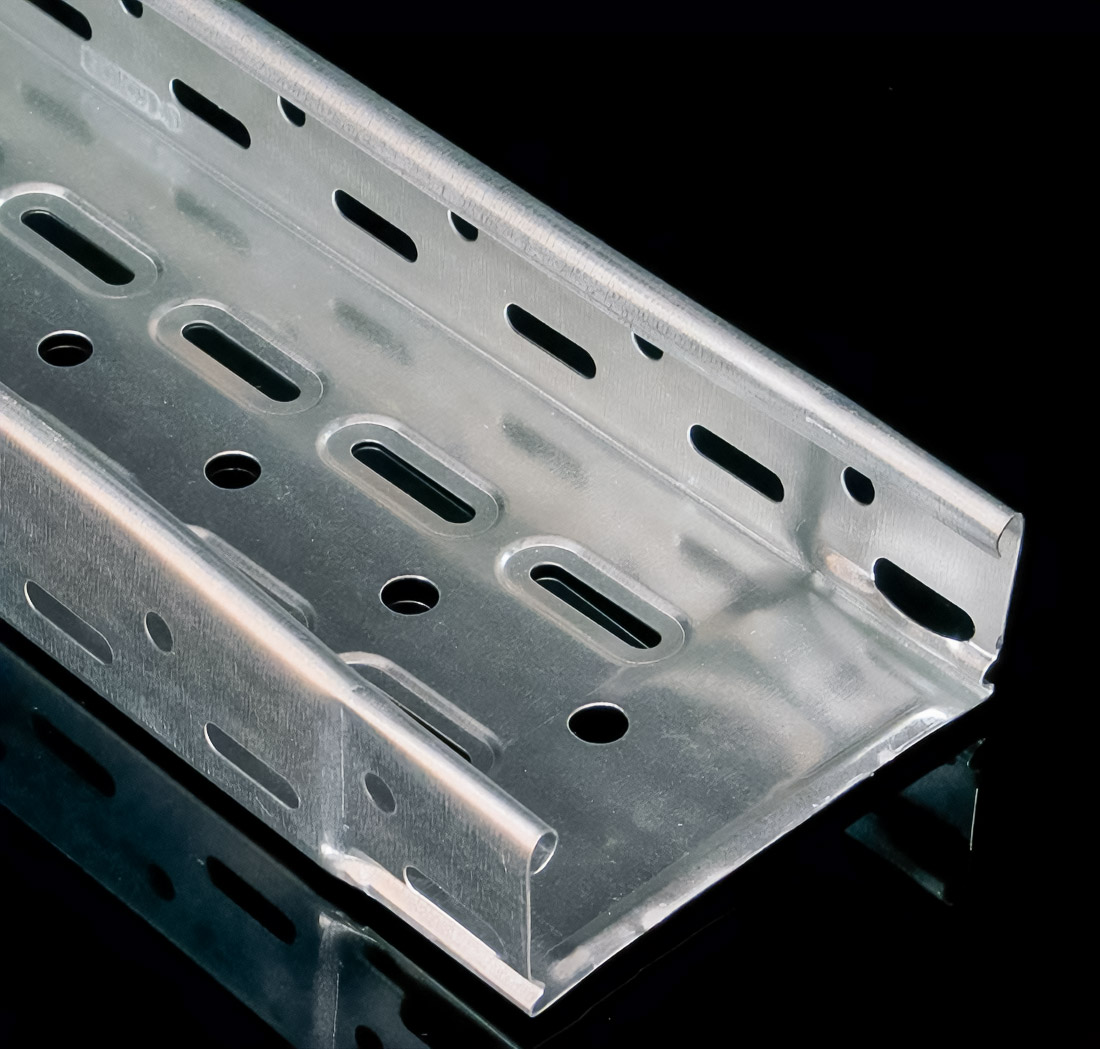

Cable trays are manufactured with specified load and size reserves, conforming to BS EN 61537, NEMA VE1 standards and megaproject requirements.

In conditions of possible delayed deliveries, a ready-made dosing rod or semi-finished products are often used to quickly assemble the structure on site.

4. The impact of delays on projects and how to minimize it

The direct consequences of delays are the failure of the deadline for the completion of facilities and rising costs. Assessing global results, delaying megaprojects can cost up to 11% of the cost or more than $1.5 trillion in global economic growth.

To offset the risks, cable tray suppliers in Dubai establish strong contacts with contractors and use digital supply management tools — BIM and ERP systems help track availability in real time.

Conclusion

In 2025, cable tray suppliers in Dubai are facing global challenges in the supply chain: delays in raw materials, rising prices, and logistical risks.

To manage this situation, they:

- diversify their sources.

- create local stocks.

- A flexible planning system is being implemented.

- They use engineering training and digital platforms to control logistics.

This approach allows timely servicing of large industrial, infrastructure and residential projects, reducing financial and time risks.

Baseball fan, shiba-inu lover, guitarist, reclaimed wood collector and doodler. Operating at the junction of art and programing to create not just a logo, but a feeling. I’m fueled by craft beer, hip-hop and tortilla chips.